Product

Product

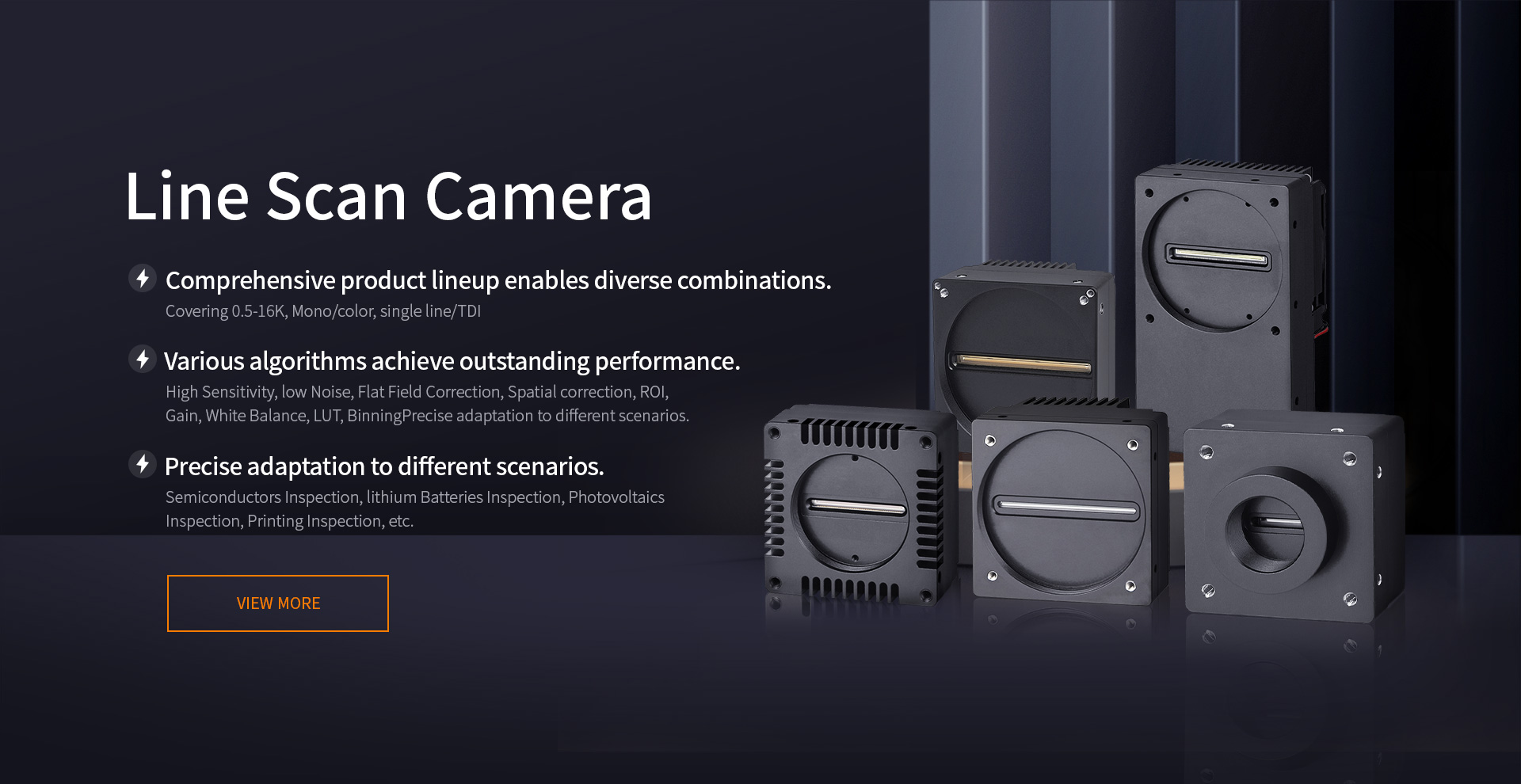

Focusing on high-end industrial imaging, providing a diversified product series, and building a comprehensive and complete solution system

About us

Hefei I-TEK OptoElectronics Co., Ltd. was established in 2011. We are a national high-tech enterprise that develops, produces and sells professional machine vision components. I-TEK is headquartered in Hefei High-tech Zone, China. We have offices in Shenzhen, Suzhou, Beijing, Wuhan, Chengdu and other cities, and have established friendly partnerships with machine vision companies in Germany, Japan, South Korea, Singapore and other countries.

-

Established2011

Established2011 -

Product variety200+

Product variety200+ -

Declare patent230+

Declare patent230+